|

Getting your Trinity Audio player ready... |

The latest technology is electronic products: smartphones and smarthome appliances, medical devices and industrial systems. A successful electronic product is always followed by a well organized design. Electronic product design services become very important in this place. These services assist in assisting businesses to convert ideas into dependable, manufacturable and marketable electronic products.

What is the design of electronic products?

Electronic product design services are engineering services carried out by professionals to take care of an electronic product design lifecycle. This involves conceptualization, hardware and software design, prototyping, testing and manufacturing preparation.

Startups, SMEs, and large enterprises use these services to design products based on consumer electronics, IoT devices, wearables, industrial controllers, automotive electronics, and medical devices.

Electronic Product Design Services Important Elements.

- Product Concept Analysis and Requirements Analysis.

It will start with knowledge of the product concept, intended users, and specifications. The designers examine technical feasibility, cost goals, regulatory requirements, and market requirements.

- Electronic Hardware Design

This entails the choice of parts including microcontrollers, processors, sensors, power supplies and communication modules. Sematics are designed by engineers and the hardware is designed to meet performance, safety and power efficiency requirements.

- PCB Design & Layout

Printed Circuit Board (PCB) is a very important component of electronic products design services. An efficient PCB guarantees signal integrity, thermal management, and small size factors whilst being reliable.

- Firmware and Embedded Software Development.

Firmware is the control of the hardware functions. This involves embedded software writing to control the devices, sensor data processing, power management and communication between them.

- Prototyping & Validation

Prototypes are constructed to confirm the functionality and design suppositions. Test assures that the product does what it is supposed to do in a context of real world use and points out the problems at an early stage.

- Testing & Compliance

The products should be in accordance with the industry standards and regulations like safety, and other requirements that include electromagnetic compatibility (EMC), as well as environmental standards. Quality and regulatory preparedness is provided by extensive testing.

- Manufacturing Support

Designing of electronic products also incorporates design for manufacturing (DFM) and design for testing (DFT) in how to avoid any difficulty in moving a prototype to mass production.

What is the significance of having electronic product design services when dealing with modern products?

- Faster Time to Market

Professional design services ease the development process through the use of established processes and tools that allow businesses to bring products to the market quicker in competitive markets.

- Increased Quality of Products and Reliability.

Considerable engineers create goods keeping in mind its performance, durability, and long-term stability making the probability of its failures after its introduction into the market minimal.

- Cost Optimization

Early design choices have a strong influence on the manufacturing and lifecycle costs. Electronic products design services aid in the optimization of component selection, PCB layout and power saving to lower their total costs.

- Innovation & Competitive Advantage.

As technological progress is fast, the businesses should have innovative features to be unique. Design services allow combining new technologies, like IoT connectivity, AI processing, and low-power systems.

- Scalability & Future Readiness.

An electronic product with proper design can easily be upgraded or scaled. Flexible designs and modular frameworks enable the corporation to adjust to the requirements of the market in the future.

- Risk Reduction

Design validation through testing and prototyping helps companies to minimize technical risks and eliminate costly resolutions and recalls.

Examples of industries that use electronic product designing services can include the following.

Consumer Electronics Smart devices, home automation products.

IoT and Smart Systems- Smart infrastructure, connected sensors, gateways.

Healthcare/Medical devices Diagnostic equipment, monitoring systems.

Electronics, Industrial Electronics Automation controllers, power systems.

Automotive & Mobility Control units, infotainment, safety systems.

Wearables- Fitness trackers, health monitoring appliances.

Selection of the Right Electronic Product Design Partner.

Businesses should look at: when choosing an electronic product design service provider:

Practice in related industries.

End-to-end (hardware, software, testing) capabilities.

Mechanical and production assistance.

Hypersensitivity towards quality, compliance and scalability.

The correct partner will provide easier development and a superior market performance.

Frequently asked questions Electronic Product Design Services.

Q1: What are the contents of electronic product design services?

The common services offered by these are concept development, hardware and PCB design, embedded software development, prototyping, testing, compliance support, and manufacturing readiness.

Q2: Is electronic product design service appropriate to startups?

Yes. Start ups usually use the services of a designer as a way of mitigating development risk, cost control, and speed to market.

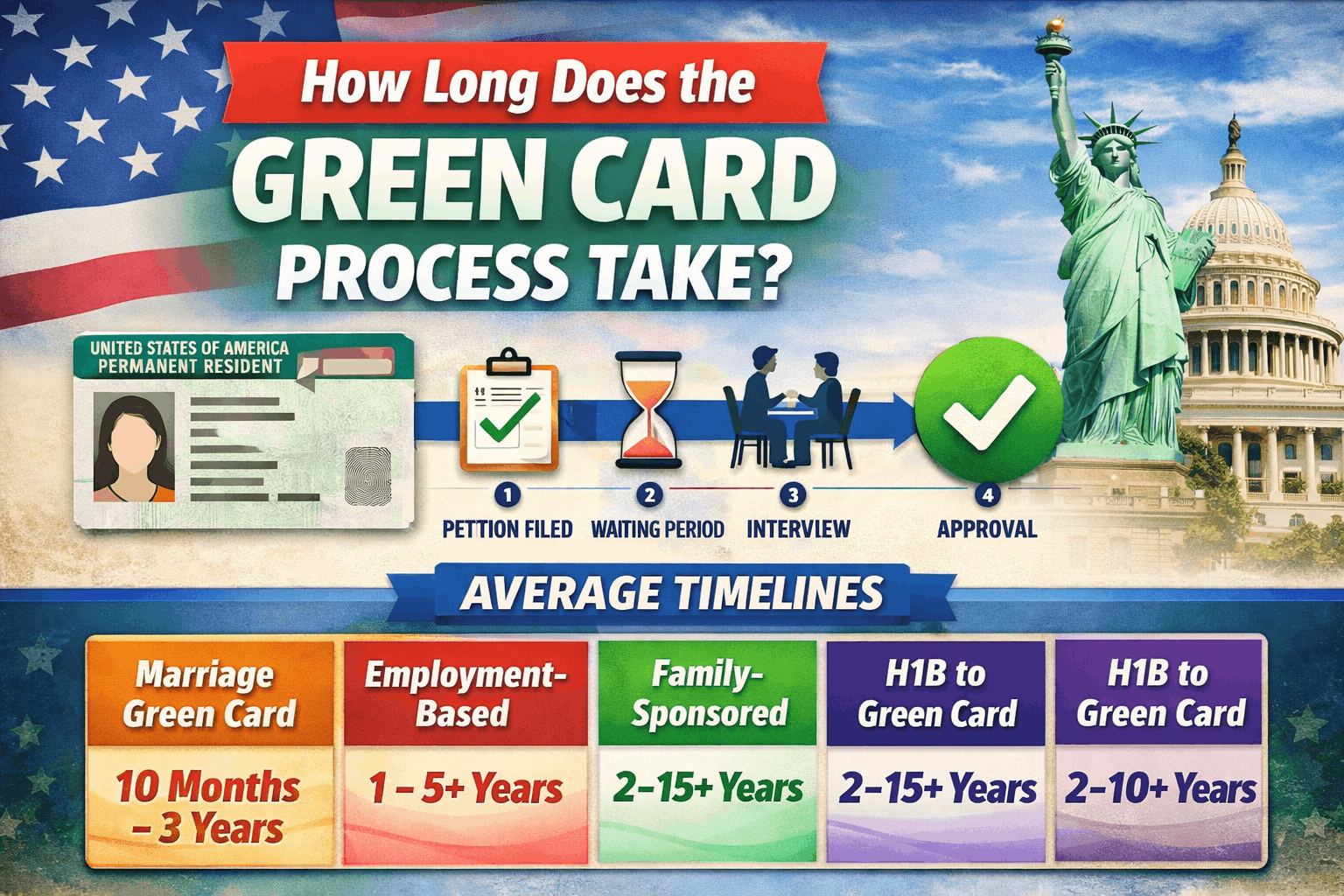

Q3: What is the length of time in the design of electronic products?

Time line is dependent on the complexity of the product. Basic design can take a few months whereas sophisticated products can take six months and above.

Q4: Is these provision of services manufacturing?

The majority of providers do assist in manufacturing preparation and may liaise with contract manufacturers, but mass production is often treated differently.

Q5: What is the significance of PCB design?

The design of PCB has impact on performance, reliability, size and cost. Unintelligently designed PCB may create signal problems, overheating, and product failure.

Conclusion

Designs of the electronic products are fundamental in the construction of the contemporary electronics products of high quality. They combine the engineering skills, innovation, and process organization to take ideas and make them successful market solutions. In the era of technologies, the sphere of professional electronic products design services no longer remains a choice but a major contributor to the long-term business success.